Monday, July 9, 2012

1996: the Gamma rapier weaving machine

In 1996 Picanol launched the Gamma-rapier weaving machine. Initially, the machine was driven by a clutch/brake-unit. However, in 1999, it received a direct drive switched reluctance engine. The engine was dubbed SUMO Super Engine (Sumo through its ability to shift a large weight very quickly). The application of this technology represented a new milestone in the electronic control of weaving machines, as the machine speed can be varied during the weaving process. The Gamma is also equipped with the Quick Style Change system, and reaches a speed of 600 weft insertions per minute. Picture: Prince Philip starting up new weaving machines at the reopening of Woodard Textile Mills Sdn. Bhd. (Malaysia, 1996)

Monday, June 11, 2012

1995: technological innovation at the foundry

The technological innovation continues in the 1990s. A new melting plant was installed at Proferro in 1995, a modern duplex unit with a furnace capacity of 18 to 27 tons per hour. In 1996, Proferro started with the production and sale of nodular cast iron in response to the changing market demand. That year, the long-heralded investment for the finishing of frames (or bâtis) became a reality: three horizontal numerically controlled machining centers of the Mandelli-type were connected to a central computer.

Friday, May 25, 2012

1993: expansion in Asia

In 1993, Picanol was accredited with ISO 9001 certification, the international standard of quality management for the products and services provided. Picanol became the first weaving machine manufacturer worldwide to be accredited the ISO 9001 certificate. In his acceptance speech, Patrick Steverlynck emphasized the importance of quality in order to keep on playing a leading role on a global scale. Picanol also expanded its activities in Asia. In 1993, Prince Albert of Belgium opened Picanol’s renewed training center in Shanghai. In 1994, the group expanded further by founding the joint venture Suzhou Picanol Textile Machinery Works (SPT). The assembly of weaving machines in China began in 1995 with the GA733 (the Chinese version of the GTM-A). From that year onwards, the first GTMs rolled off the assembly line in China. Eberhard Huettl, Urbain Osaer and Marc Trioen were onsite to oversee everything. At the beginning, the machines were only destined for the Chinese market.

Friday, May 4, 2012

1993: launch of the Omni & Delta

In early 1990, Picanol produced a record number of machines, and realized the highest turnover in its history. However, in the second half of the year this success came to an abrupt halt. Due to the downturn in the economy, the recession in the USA and the Gulf crisis, many orders were cancelled, and others postponed. These setbacks did not prevent Picanol from continuing its course. The company invested in new assembly lines, new equipment and assembly robots. R&D also continued to play an essential role. In 1992, the company introduced a new generation of airjet weaving machines: the versatile Omni and the less extensive Delta. The Omni offered new possibilities for weaving different colors in narrow and broad reed widths. Both machines were made available with the unique Quick Style Change system, with which a single person could equip and set a loom for a completely different fabric in 30 minutes. The Omni (width of 190 cm) reached a speed of 1,000 weft insertions per minute, the Delta up to 800 weft insertions. Picture: advertising campaign from 1992.

Friday, April 13, 2012

1989: Farewell to Jaime Picañol and 10.000th PAT machine

On 13 August 1989, Picanol was informed that Jaime Picañol Camps, the Catalan inventor from whom the group took its name, had passed away. In 1936, he became the head of the weaving machine development department. By the end of 1936, he managed to launch the ‘Omnium’ - the first production-ready weaving machine. Jaime would remain involved with the development department until the early seventies. After his career at Picanol, he returned to Spain. In 1989, as two-thirds of sales of the foundry were realized outside of Picanol, the foundry division was split off from the other activities and made into a separate company, Proferro NV. Also in 1989, Picanol took a stake in former electronics company Protronic (now PsiControl Mechatronics). On 10 November 1989, the 10,000th PAT-airjet weaving machine was installed at the Italian Gruppo Miroglio Tessile. Eduardo Miroglio pressed the start button under the supervision of Patrick Steverlynck.

Wednesday, March 28, 2012

Farewell to the shuttle loom

On 22 January 1988 the last flying shuttle loom rolled off the assembly line; a CMC-U-MDC TC, tire cord of 176 cm – and it meant the end of an era. Over a 52 year period, Picanol had supplied over 170,000 flying shuttle machines worldwide. After being stuck for a long time on the quay, Picanol’s very last flying shuttle weaving machines were installed at the African Textile Mill, Uganda - between November 1989 and May 1990. Also in 1988, the first Chinese customer of Picanol, Nantong No. 3 Cotton Mill, paid a visit to Ieper. In 1979, Picanol had supplied 100 MDC weaving machines to this mill, which marked the breakthrough of Picanol in the Chinese market. In June 1988, aluminum was cast for the last time at Picanol. The aluminum foundry had been active for over thirty years, for example with the quality casting of plate models under low pressure.

Monday, March 12, 2012

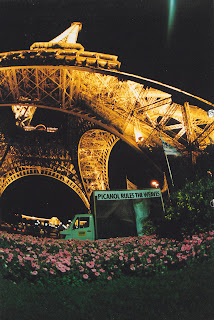

Picanol rules the weaves in Paris

1987 was again an ITMA-year, for the second time in Paris after 1971. ITMA Paris attracted 160,000 visitors, five times the amount of the first ITMA in 1951. The first ITMA exhibition (Internationale Textilmaschinen Ausstellung) was launched by CEMATEX in 1951 and has taken place with great success every four years since then. Picanol was present as well. Around the "Parc des Expositions" several billboards appeared with Picanol posters reflecting the new image of customer satisfaction: Picanol Rules the Weaves! In 1987, Picañol changed the spelling of its name to Picanol (without tilde), and built the Picanol Service Center in Shanghai. Also during that year, modifications were made to the production facilities in Ieper. The company split the production division into smaller units, which meant that similar work pieces could be grouped together and finished in a specialized production cell. Picanol also published that year the first edition of its very own magazine Picanol News, which informs customers and prospects on a regular basis of new developments. The magazine is published in four languages: English, German, French and Chinese.

Subscribe to:

Posts (Atom)